As stated previously, I recovered a working gas sensor board from a combination carbon monoxide and natural gas detector that was going into the trash. There are some other parts that are perfectly usable. For example, the detector has a thick plastic 9-volt battery snap and 9 V AC adapter that can be removed with snips.

I can get some additional parts out of this particular device. Unusual for consumer electronics manufactured in 2005, the motherboard consists of through-hole components that many hobbyists prefer.

Heat gun for mass desoldering.

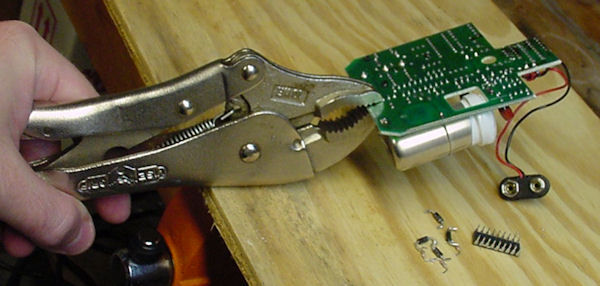

As previously demonstrated in removing a Big Trak microcontroller, a heat gun can desolder multiple pins at the same time. Large or tall components can be removed by heating the board while a clip or pair of pliers pull at the part from the other side. Unfortunately, this is inconvenient for smaller parts (resistors and diodes) and surface-mounted components.

Knocking parts loose during desoldering.

A faster method involves tapping the board against a piece of wood while heating it with the heat gun from the soldered side. All pieces (except those with bent leads) simply fall out.

Locking vise-grip pliers take the stress out of your hands by firmly holding the board for you. The pliers also reduce your heat exposure by allowing you to position your hand farther away.

Besides the AC adapter and gas sensor board, the Nighthawk CO detector yielded a pile of useful electronics.

Parts scavenged from an old CO detector.

Although the electronic parts appear to be fully functional, their physical condition is imperfect.

Short leads and molten solder residue.

The wire leads are trimmed short. This isn’t unmanageable if you plan on soldering them to your own board. However, they are less useful in solderless breadboards, which usually need slightly longer leads for full insertion.

More concerning is the random bits of solder that came from the spray of molten solder while tapping the board. Unless cleaned, the old solder will short some pins on the chips and will prevent some leads from fitting into holes.

Worse still, you have to imagine this solder contains the element lead. So, after desoldering, I’ve got it all over my hands, the wood board, and I might have inhaled some microscopic airborne droplets.

Unless a component is expensive or irreplaceable (such as the TMS1000 chip in the Big Trak), you have to question whether extracting these parts is worth the trouble and potential health hazards. Furthermore, given their age, usage, and rough desoldering, can you rely on these parts?

One last point of interest -- little specs of black material appeared on the wood board during desoldering. It turns out that I accidentally melted the plastic cover of the carbon-monoxide sensor.

Melted and ruptured charcoal filter on carbon monoxide detector sensor.

The black pieces are activated carbon. Carbon binds to many chemicals, but allows carbon monoxide to pass through. In doing so, the carbon filter reduces false detections due to other gases.

Because the other chemicals bind to the carbon, it eventually becomes saturated, and loses its effectiveness. Along with the slowly evaporating liquid electrolyte in the carbon-monoxide sensor canister, the carbon filter is another reason why the detector has an expiration date.

Normally, we don’t think twice when we discard an obsolete or malfunctioning device. Automation and complexity makes it less expensive to mass produce a new one, rather than repair the existing one.

In this case, there was a lot to learn and there were a few reusable parts. Without breaking down the gas detector board, it wasn’t possible to determine if the gas alerts were due to software a bug, a questionable circuit, a failing component, a defective gas sensor, or a legitimate detection of a household chemical. But, there were a number of interesting points that made the inspection worthwhile.